Innovation

Al+

Al+ is our newest aluminium alloy and it has a high strength-to-weight ratio so we can build wheels that are tougher and more durable than our wheels that use our standard alloy, while still being light.

We are always pushing ourselves to create better products for riders so we have to push the limits of material. Our standard alloy allows us to build wheels that are extremely light but we wanted something that was a little more durable. We could have thickened our standard alloy but by switching to Al+, we can make wheels that are significantly stronger and harder. In fact, gram-to-gram, Al+ is more than 10% stronger than our standard alloy.

AVT

AVT is a material that we place in our carbon fibre wheels to make them more impact resistant and better able to absorb high frequency vibrations.

Using a high-tech material normally found in aerospace and military applications, we are able to make carbon wheels with super high tensile strength and which significantly dampen vibration. We call this special material, Anti-Vibration Technology. Or AVT because it’s just easier and takes less time to say.

AVT shares a lot of the same properties as Kevlar. We are not aiming to stop bullets, but the strength of Kevlar is one of the key factors we wanted from AVT in our wheels. Weight for weight, AVT is eight times stronger than steel, resistant to high temperatures, fatigue and impacts.

The AVT material found in TOKEN wheels is bound with carbon to form a layer inside the rim that distributes impact evenly. When compared to other existing methods of impact damping, our AVT layer provides greater overall wheel strength.

Another property that AVT has is its ability to reduce the amount of vibration that is passes through to the bike to the rider. Less vibration means, of course, that you spend less of your energy on absorbing the buzz so you have more energy left to ride faster or longer.

AVT is truly an innovative advance in wheel technology that makes wheels stronger and riding more comfortable.

CFT

Ceramic Flame Spray Technology

Not all ceramic coatings are equal. Ceramic Flame Spray Technology is a re-engineered thermal spray process. The ceramic layer is applied to the whole rim using high-speed flame, but instead of traditional “one-shot” style, we divide it into countless instantaneous deposits. This can totally avoid overheating the rim and creates a much more even thickness as well as roughness. We chose the specific ceramic material that is best for rim brake use, and the unique denim-blue color is its natural appearance.

Conti-Fibre

Continuous Fibre creates a lighter stronger carbon rim.

CONTI-FIBRE is an innovative carbon rim manufacturing process that we've invested in for more than 3 years. The main part of the rim is pre-formed by machine so the structure is uniform and symmetrical. Excess material overlaps and human error are eliminated, so the rim structure has virtually no weak point. This results in not only a lighter, but also a stronger rim. We can even tweak the rim structure in the machine to optimize it for different applications, such as rim brake or disc brake.

Compression Relief Design

These patented grooves make the BB more frame bore tolerant and store grease.

Multiple carefully designed grooves are formed on the outer surface of the bottom bracket cup and therefore split the surface where the cup contacts the frame bore. This allows slight material deformation and makes the BB more tolerant to frame bore dimension variation. These patented grooves also store grease making the BB even less prone to creaking.

Conti-Wave

Conti-Wave machining reduces chain noise as it minimizes the contact surface against the chain.

Chain enters the rear derailleur at various angle. The Conti-Wave tooth profile designed for lower pulley ensures smooth pulley-and-chain engagement regardless of gear position. The continuous chamfer form on the teeth edge reduces contact area between the teeth and chain inner plates by 82.5%, increases the efficiency even further while guiding the chain perfectly.

Crash Replacement Policy

Crash Replacement Policy

Accidents happen and we can’t prevent them but if you break your rim in a crash or some other incident then we will give you 35% off a replacement rim. *Some conditions apply, contact your local distributor or us through the contact form under the "About" section at the top of the page.

Diametric Spoke Pattern

The Diametric Spoke Pattern is a method of lacing wheels that builds stiff, light and strong wheels.

The Diametric Spoke Pattern of the spoke lacing is the spoke pattern that is best able to handle the different stresses that are placed on a rear wheel. It consists of a radially laced spoke on the non-drive side, which is then centred between two, triple-crossed spokes on the drive side.

This method of lacing is very strong and highly resistant to rider induced flex. The wheel is very stiff and responsive so it can respond to accelerations very well. Because of the inherent strength of this lacing, it allows the wheel to be built with fewer spokes without sacrificing strength.

It took a lot of research and testing to perfect the Diametric Spoke Pattern but it’s worth it because it yields a high quality wheel.

Fusion

Fusion technology marries aluminum and nylon to give you a high-performance and squeak-free bottom bracket.

TOKEN’s Fusion bottom brackets are made with fibre-coated aluminium shells that precisely press into your frame. The fibre protects the frame from damage and makes the bottom bracket noise-free. It also allows the bottom bracket to be fit in frames that are slightly out of tolerance, without damaging the frame, crankset or bearings. We use aluminium to support the bearings so they resist side-to-side movement and last longer. When the unique Fusion construction of the shell is matched with our bearings, it provides an incredibly durable and very smooth bottom bracket.

Multi-Function

Cross platform compatibility across all TOKEN products

Optimizing a product's functions has the ability to add value to the product and ultimately the consumer and that is exactly what we are doing with our Multi-Function designs and integration. Where ever you see the Multi-Function icon you will know that the product has been optimized to offer the needed function and more into a single product. This cross platform compatibility provides an option for increased usage of products and also the opportunity to upgrade your next bike with Token products.

OAD

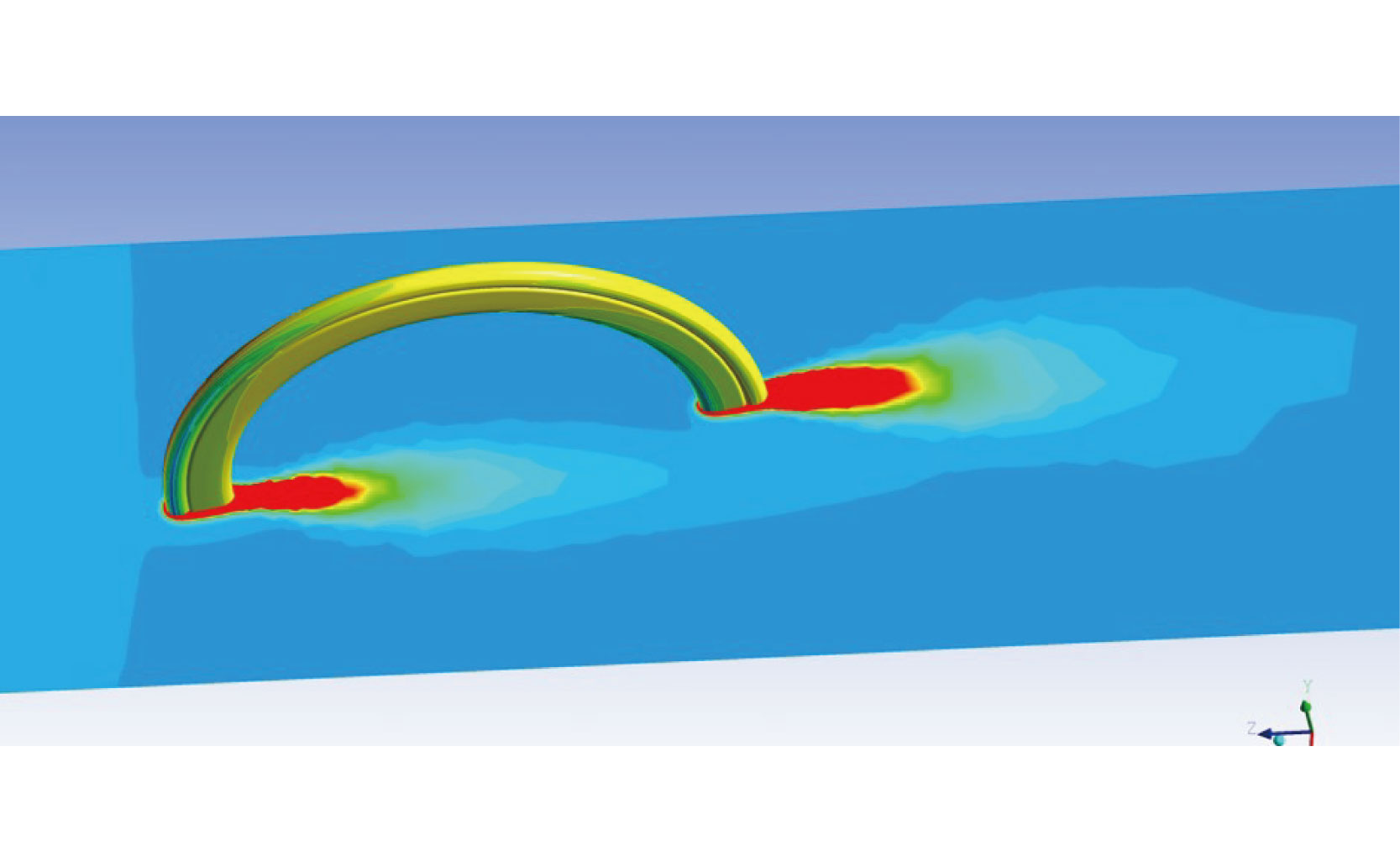

Optimized aerodynamic design

OAD Trained engineers can design bicycle rims, but building them so they ride as fast as they look requires more than just a bachelor's degree and a pair of thick-rimmed glasses. OAD (Optimized Aerodynamic Design) rims are formed using extensive CFD (Computational Fluid Dynamics) analysis to ensure the wheel performs to our highest expectations at both 0° and a 10° yaw angle, which represents most real-world riding conditions.

Premium Bearings

Premium Bearings are our high carbon steel bearings.

Premium Bearings are our high carbon steel bearings. We make these bearings to higher standard so they run smoother and last longer. They are suited to people who ride often in all conditions.

RAR

Relevant asymmetric rim

An asymmetric rim profile is a well known method to gain better balanced spoke tension when designing a symmetrically perfect wheel is not an option. After many cups of coffee and meetings with various engineers, we realized that the asymmetric properties for different rim widths, different riding conditions, and different materials used should not be the same. Our research has shown that rims should have a relevant spoke bed offset, and that's what the term RAR (Relevant Asymmetric Rim) refers to.

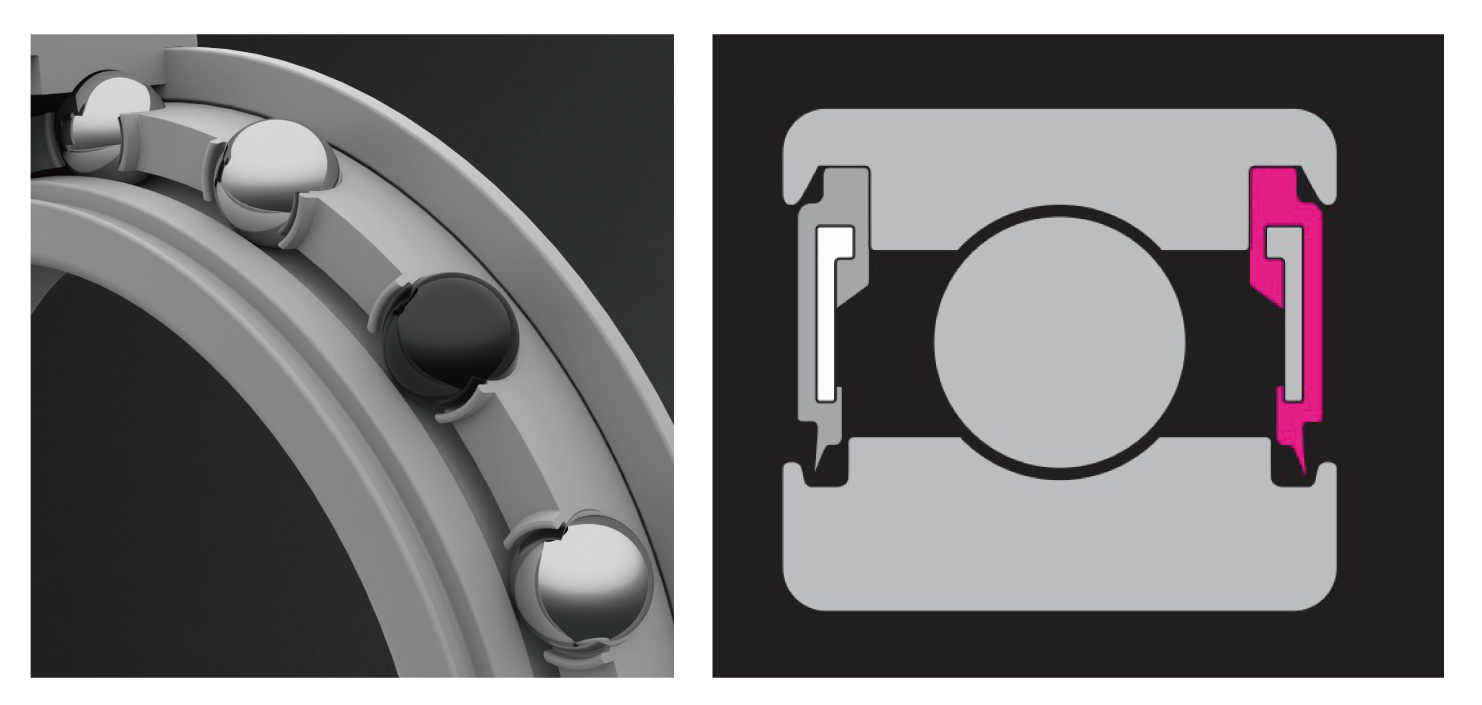

Sealed Bearings

Sealed Bearings are our standard bearings that spin smoothly and are durable but remain affordable.

Sealed Bearings are our standard bearings that spin smoothly and are durable but remain affordable.

Stainless Premium Bearings

Stainless Premium Bearings are found only in our headsets.

Stainless Premium Bearings are found only in our headsets. They are finished to the same high standard as our Premium Bearings, but the balls are made of stainless steel so they won’t rust even in the worst conditions.

Swiftedge

Wide rims offer several of advantages over narrow rims, most important of them being more speed.

All of our rims that are 25c or wider are called Swiftedge; there are several advantages to using rims this wide. Wide rims allow you to run tyres wider than standard 23c models, without worrying about having the tire roll off the rim. A wider rim changes the shape of the tyre when it is inflated, allowing it to be better supported. The improved shape of the tyre allows for lower rolling resistance with greater grip and comfort. Another advantage is the smoother transition between the tyre and rim, which provides an aerodynamic benefit. Any small weight gain is more than outweighed by increased speed and comfort. The Swiftedge rim gives you a little edge that you’ll appreciate when you’re on the rivet.

TBT

TBT bearings are made with ceramic balls and extremely hard races for very low rolling resistance and long-lasting performance.

TBT is the name we have given to our special ceramic bearings because they are different than “standard” ceramic bearings. The ball bearings in our TBT bearings are ceramic so they are very, very round and very hard. They won’t deform and increase their surface area under the weight of a rider, which leads to more resistance and slows you down.

The one problem with ceramic balls is they are very hard and easily damage standard races made of stainless or normal steel. Without a specially designed race, in a short time you’ll end up with a lot more friction than standard set of sealed bearings. To fix the problem of soft races, we coat our steel races in titanium nitride.

The titanium nitride coating is serves two functions – it protects the races from corrosion from the balls themselves. Titanium nitride is very hard so the ceramic balls don’t damage the races as easily as non-treated races. In addition, the coating protects the steel from corrosion so TBT bearings can be used year-round without any worries.

When compared with standard bearings, TBT bearings are lighter and have less friction so if you are looking for an edge, these are the bearings you want.

TFT

A unique bearing that combines ceramic and stainless steel bearings for extreme smoothness and increased longevity.

TFT is the name of Token’s Tiramic bearings. These bearings consist of both ceramic and stainless steel balls, which creates a hybrid bearing. Hybrid bearings are famously durable and smooth rolling which makes them perfect for the tough conditions and stresses that a bike sees.

To take the bearings to an even higher level, we manufacture them to ABEC 5 standards. This means they are more round and run smoother than industry standard bearings. To keep the balls safe, our bearings run on stainless steel races so they resist corrosion and are tough enough to withstand thousands of kilometres of riding.

To keep these high-performance bearings rolling smoothly, they are packed with high quality Klüber grease and are protected with out specially designed washers. The washers we have designed are both thin and flexible. They won’t swell or deform and will keep dirt and water out just as well as thicker washers. Our design allows the bearings to run with less friction, which saves you energy.

All of this takes a lot of time and work to do well but it’s worth it for the best bearings we sell.

Tgx

We use a special compound of epoxy when making our carbon rims which allows the rim to withstand high temperatures found when

TgX = Tg-eXtreme. Tg (glass transition) is the temperature at which the epoxy used to treat carbon rims begins to deteriorate. When the epoxy reaches Tg the outward pressure of the tire and tube can cause the rim’s sidewall to deform, potentially resulting in failure. We construct our rims with a high Tg epoxy to withstand the extreme temperatures created during braking. Coupled with our specially designed carbon rim brake pads, the temperatures from braking dissipate more quickly so you descend faster without fear of overheating your rims. And there aren’t many things cyclists like more than descending faster.

Tubeless Ready

With the addition of some sealant, you can run our Tubeless Ready wheels with your favourite tubeless tyres.

There are a lot of advantages to running tubeless tyres including a more comfortable ride, better traction and fewer flats. To make it easy for you, our Tubeless Ready wheels come with airtight rim tape installed and the required valve. Simply mount your tubeless tyre, add sealant, inflate then enjoy the ride!

UCI Approved

Any of our wheels that have the UCI Approved logo are approved for use in UCI sanctioned mass start races.

There are an almost endless number of rules regarding equipment for use in UCI sanctioned road races. If your local race doesn’t require you to follow UCI rules regarding equipment then feel free to use any wheel you want. However, if the race requires that your bike be UCI legal then you can use any of our wheels that have been tested and approved by the UCI. Just look for the UCI Approved logos that appear on the pages to know which wheels conform to the rules.

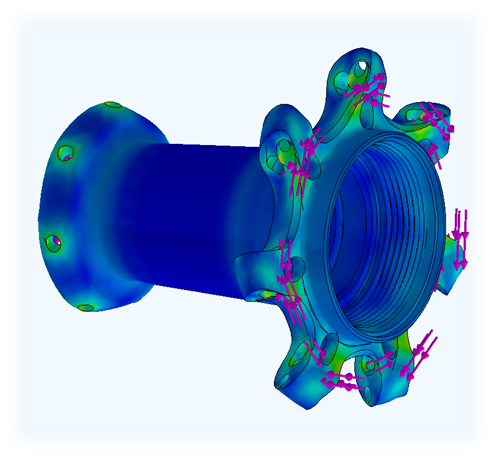

Weapons Grade Machining

We use 5-axis CNC machines to precisely machine our hubs so they perform at an exceptionally high level.

The military uses 5-axis CNC machining because they need to have very precise parts to make sure missiles land in the right place. We also use 5-axis machining, though our high-end hubs aren’t equipped with missiles. We use this kind of CNC machine because it allows us to build hubs very precisely; this means they are stronger, lighter and more durable than standard CNC machined hubs.

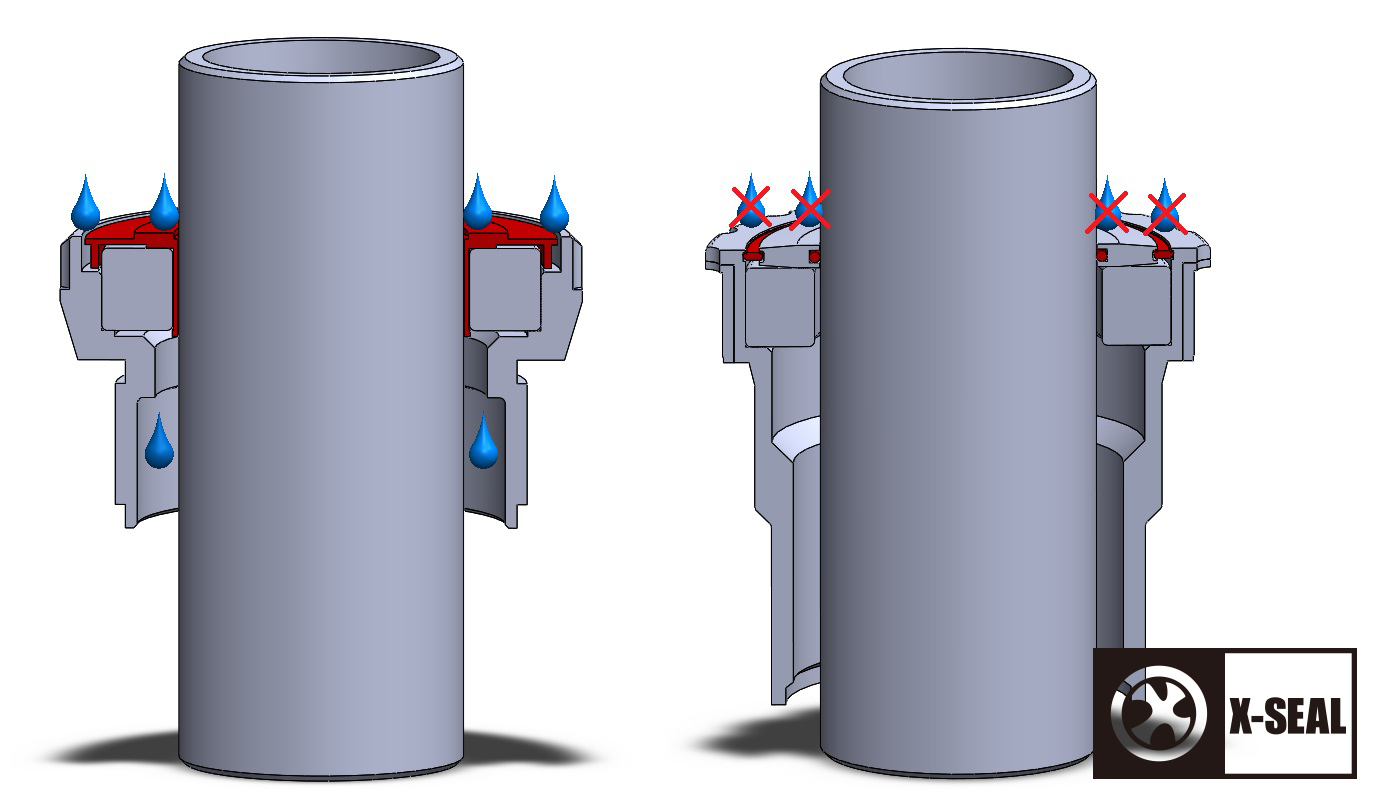

X-Seal

TOKEN’s X-Seal technology keeps bearings protected from dirt and water, with very little friction for a free-spinning bearing.

To keep bearings running for a long time, it needs to have good seals to keep moisture and dirt out. Water and dirt destroy bearings in a very short time. It’s easy to use a thick seal to keep elements out but this causes a lot of friction, which saps energy and makes you slower.

X-Seal technology is a patented seal that we use on our bottom brackets. The seals are made of two rubber rings that are housed in a CNC machined alloy cover. This allows us to make seals that are very precise and allow for less contact between the rotating parts in order to reduce energy-wasting friction. In addition, the seals provide better protection for the bearings since there is less space for the elements to get past the seals. X-Seal equipped TOKEN bottom brackets last longer, run smoother and waste less of your energy.

Y-Cut Axle

Details matter so we patented a unique method of cutting weight from skewers while maintaining strength.

When your goal is to make the best products you need to pay attention to the smallest of details and our Y-Cut skewers exemplify this. On our Y-Cut skewers we mill out a small portion of the titanium axle so it resembles a “Y” in order to save weight. It saves about 6 grams per set and the skewer still passes all the clamping tests. In fact, our titanium Y-Cut skewers can clamp with as much force as our standard stainless steel skewers. It’s just one more example of the craftsmanship found in all our products.

2 Year Warranty

2 year warranty for wheels

All our wheelsets are covered by TOKEN’s crash replacement policy.

3 Year Warranty

3 year warranty for wheels

For particular TOKEN high-end carbon wheels, we offer 3 year warranty.

5 Year Warranty

The Shuriken Oversized Pulley System comes with a 5 year warranty.

The Shuriken Oversized Pulley System comes with a 5 year warranty.

EOM

Eccentric Orbital Motion of Upper Pulley Wheel

Larger upper pulley wheels are efficient at the cost of trickier B-screw adjustment. To ensure the optimal compatibility with the original drivetrain, we added the EOM design to the upper pulley. And we think better shifting performance on the higher gears is a welcome side effect.

TSB

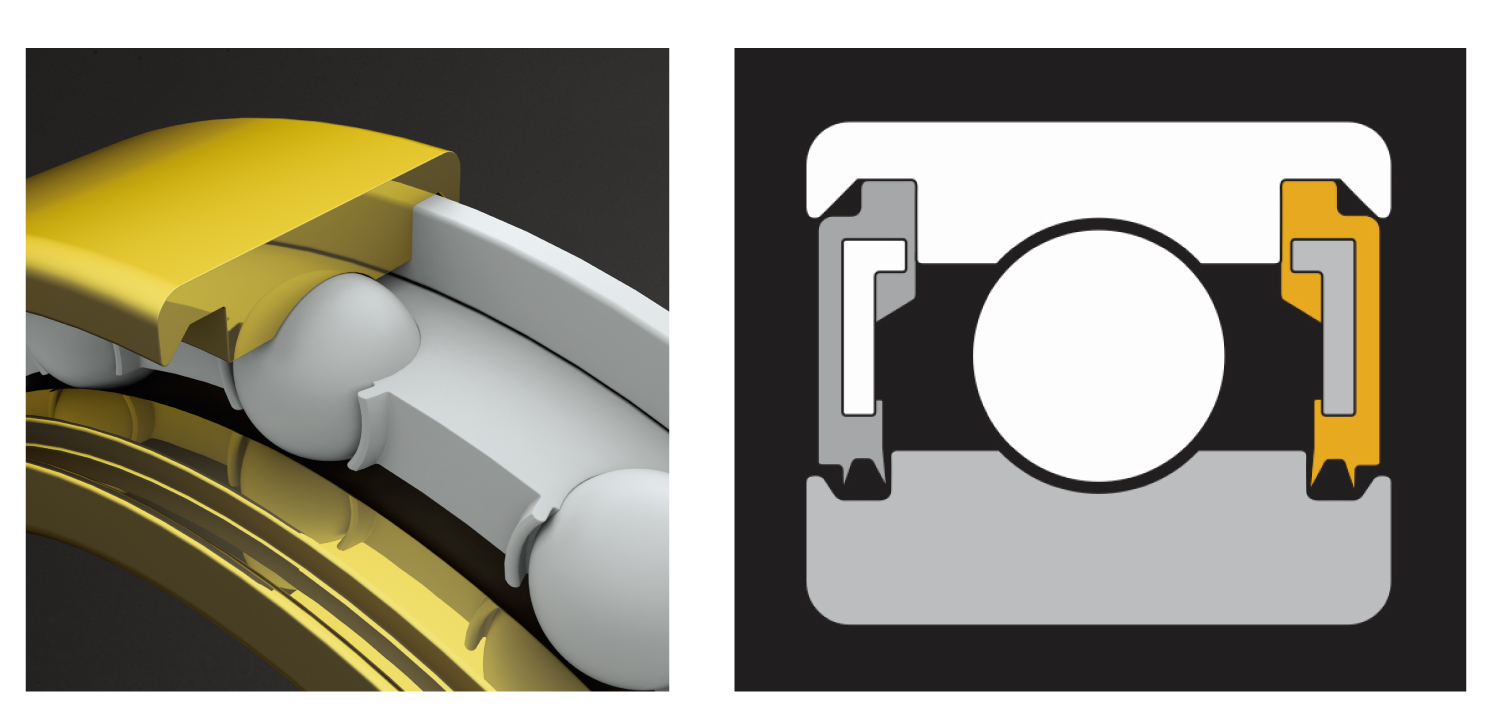

Titanium Coated Stainless Bearing

Combining the Titanium coated races of the bearing and stainless steel balls, the TSB bearing exhibits superior corrosion resistance compared to regular bearings.

Its PVD gold coating enhances the bearing's precision and adds a touch of luxury to its appearance.

The TSB bearing is a premium bearing that excels in precision, corrosion resistance, and overall quality.